which of the following is a type of machine safeguarding osha 10

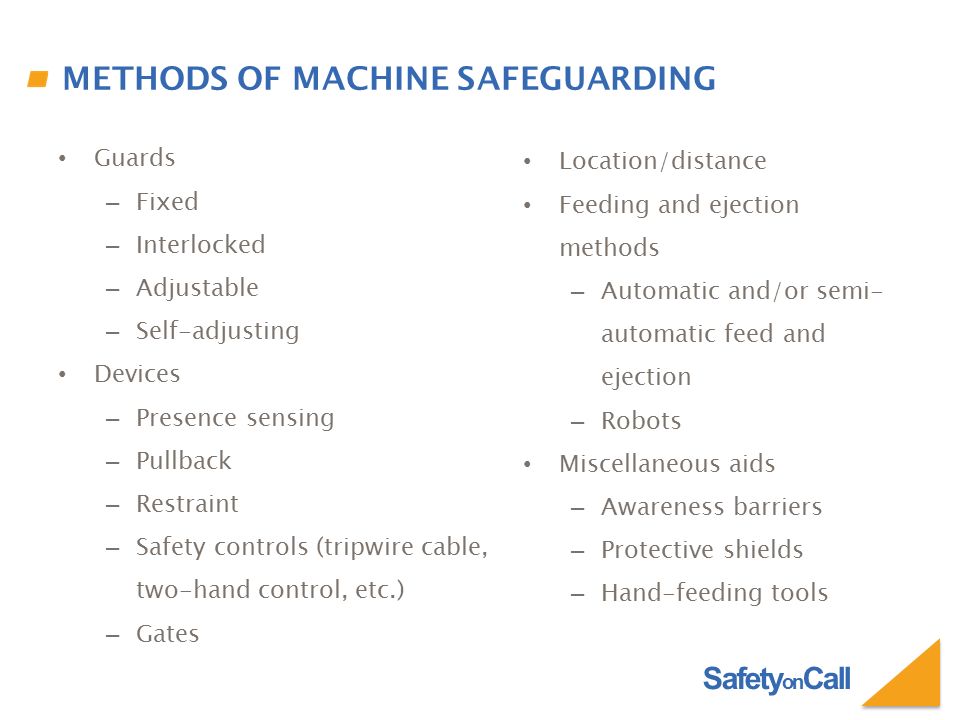

Which of the following is a type of machine safeguarding punchink feeding and ejection methods point of operation in-going nip points Feeding and ejection methods is a type of machine safeguarding. Types of Machine Safeguards Safeguarding machinery.

Machine Guarding 5 Most Common Ways To Keep You Safe

The following are all machine safeguarding requirements except.

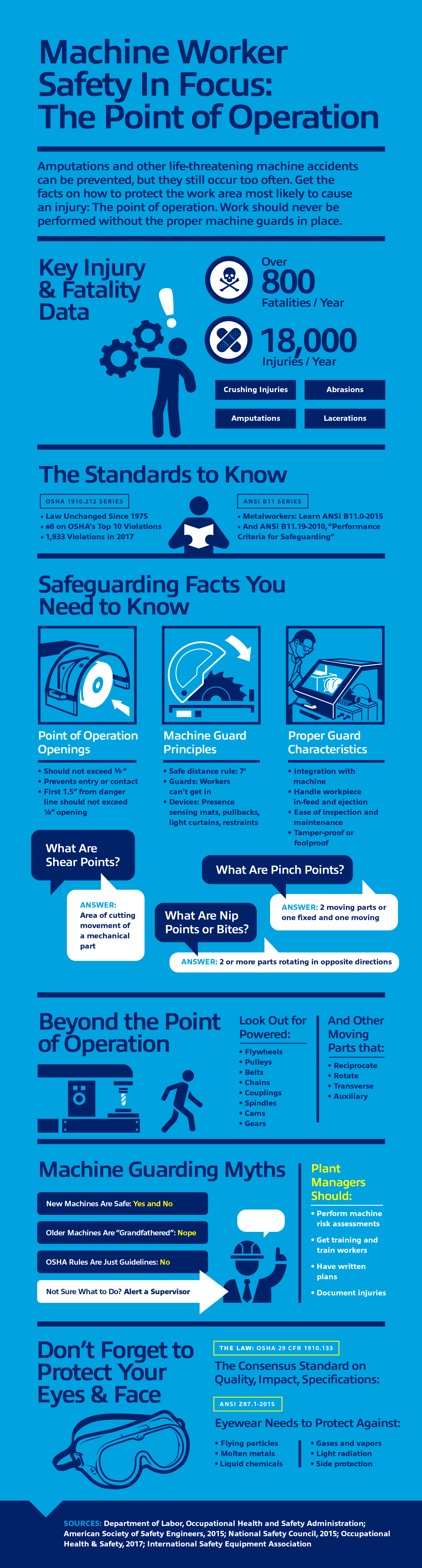

. The point of operation the power transmission device and the operating controls. Various types of machine guards available for machine guarding. A well-designed safeguarding system makes sure that the moving part is unreachable.

A wide variety of mechanical motions and actions may present hazards to the worker. O Punching O Feeding and ejection methods O Point of operation O In-going nip points. Meet the minimum OSHA requirements.

Machine guarding and related machinery viola-tions continuously rank among the top 10 of OSHA citations issued. Be firmly secured and not easily removable. The following are all machine safeguarding requirements except.

The following are all machine safeguarding requirements except. All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. Commonly Used Machine Guards 12 Table 2.

Machine Guarding Introduction. The following references provide possible solutions for machine guarding hazards. Permit safe comfortable and relatively easy operation of the machine.

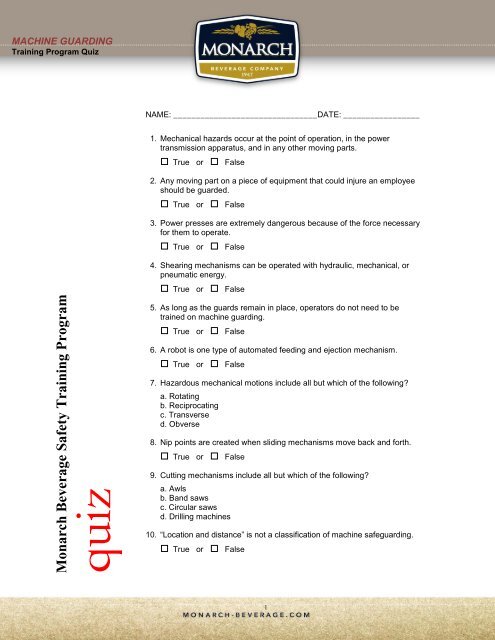

A True b False. Any machine part function or process which may cause injury must be machine guarded. Horizontal Injection Molding Machine Safety Tour.

This OSH Answers fact sheet is based. Machine guards are essential for protecting workers from needless and preventable injuries. All machines consist of three fundamental areas.

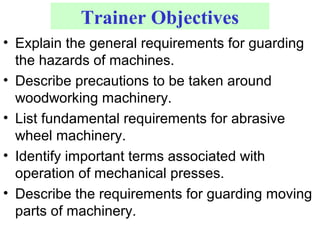

Machine Guarding OSHA 10-Hour Outreach Training General Industry. Criteria for Machine Safeguarding. Both types of safeguards need to be properly designed constructed installed used and maintained in good operating condition to ensure employee protection.

A good machine safeguarding system eliminates the possibility of the operator or another worker placing parts of their bodies near hazardous moving parts. 29 CFR 1910212 a 1 states that one or more methods of machine guarding must be used to protect operators and other employees from hazards including those created by point of operation in-running nip. Avoids creating additional hazards.

These can include the movement of rotating members reciprocating arms and cutting teeth. OSHAcademy Course Course 154 Machine Safeguarding. 29 CFR 1910212 a 1 states that one or more methods of machine.

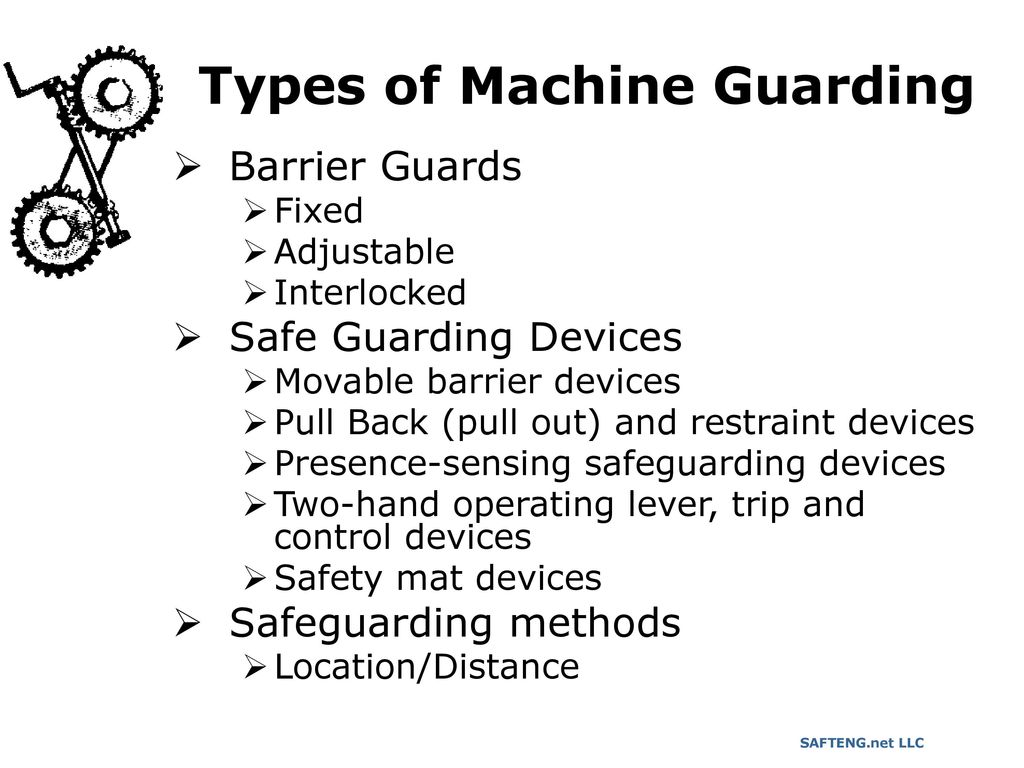

Protective measures consisting of the use of specific technical means called safeguards guards protective-devices to protect workers from hazards that cannot be reasonably removed or sufficiently limited by design. Herein what are the most common types of machine guarding. 3 Fixed adjustable access guard.

Machine Guarding OSHA 10-Hour Outreach Training General Industry. The CSA standard Z432 Safeguarding of machinery defines safeguarding as. The safeguarding system must have the following features.

A Pullback devices b Safety trip controls c Electro-mechanical sensing device d Two-hand control. Guard when periphery of blades is less than 7 above the floor or working level Guards with openings no larger than ½ Source of graphics. There seem to be as many hazards created by moving machine parts as there are types of machines.

Must prevent workers from lubricating a machine without removing the safeguard Which of the following should employers prevent in order to ensure the safety and health of workers in regards to machine guarding. 2 Fixed limited access guards. Ensure that no objects can fall into the moving parts.

Due to this fact OSHA Occupational Safety Health Administration has established a set of standards around machine guarding. Prevent workers hands arms and other body parts from making contact with dangerous moving parts. Types of Safeguarding Devices 13.

The type of operation size or shape of stock method of handling physical layout of the work area type of material and production requirements or limitations will help to determine the. Primary methods Guards Devices. X 50 Y 75 Radius 100.

Criteria for Machine Safeguarding. According to OSHA One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks The following are some key OSHA requirements for machine guarding according to. Require the operator to use both hands on machine controls thus keeping both hands and body out of danger or provide a.

Typical machines used for punching operations are power. Prevent contact keeping the workers hands arms or any other part safe from the moving part. The operator initiates the machine cycle.

Prevents employee contact with the hazard area during machine operation. Both types of safeguards need to be properly designed constructed installed used and maintained in good operating condition to ensure employee protection. OSHA has set out a few general requirements that a safeguard must meet in order to ensure maximum protection.

Machine Guarding OSHA 10-Hour Outreach Training General Industry. General Industry Machine Guarding v030117 21 Created by OTIEC Outreach Resources Workgroup Machinery That Requires Guarding Exposure of fan blades. Which of the following is an example of a safeguarding device.

A good rule to remember is. This OSH Answers fact sheet is based. To ensure that employees are properly protected from machine hazards employers must assess the workplace and identify potential.

Which of the following is a type of machine safeguarding. Machine safeguarding helps protect workers from preventable injuries in all three areas. It does not specify all machine guarding requirements or all types of machinery or equipment.

The following are all machine safeguarding requirements except. Focuses on recognizing and controlling common amputation hazards associated with the operation and use of certain types of machines. There are many ways to design and use machine safeguarding.

Allows user to take a virtual. Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement. Criteria for Machine Safeguarding.

Machine Guard Infographic The Point Of Operation Better Mro

Machine Guarding Quiz Monarch Beverage

Top Questions When Selecting Machine Guarding Wirecrafters Blog

Osha 10 Hour Machine Guarding 2

Machine Safeguarding 101 Rockford Systems Llc

Oshacademy Course 154 Machine Safeguarding Basic Module 2

Oshacademy Course 154 Machine Safeguarding Basic Module 2

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Osha 10 Hour Machine Guarding 2

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Chapter 1 Basics Of Machine Safeguarding

Machine Guarding Ppt Video Online Download

What Is Machine Safeguarding T P Supply Co

Oshacademy Course 154 Machine Safeguarding Basic Module 2